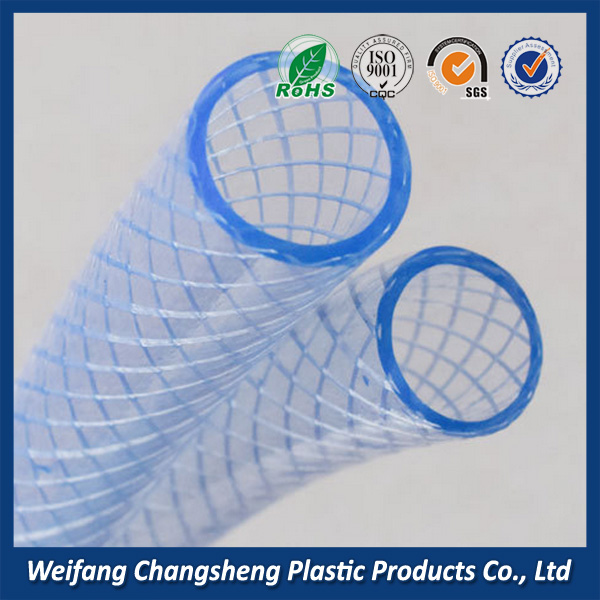

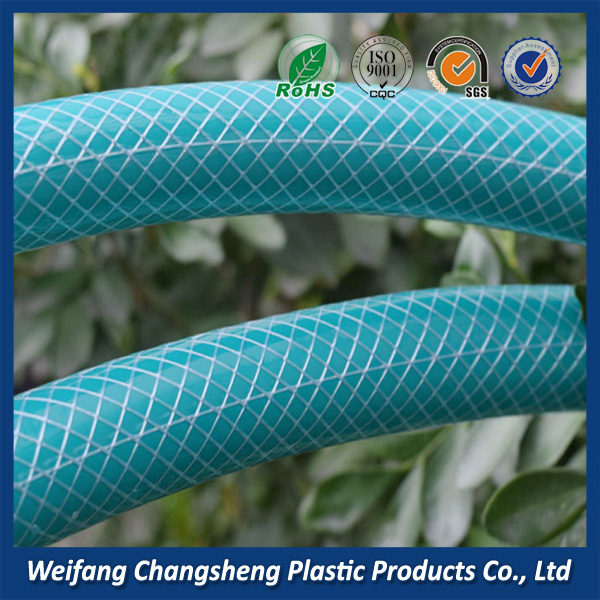

Products: High-quality PVC high-strength bright fiber yarn, non-toxic tasteless, high-quality food hygiene PVC composite material. Smooth mesh tube with polyester filament. Clear and transparent tube, easy to control the delivery of liquid flow. Strong adhesion inside and outside the layer, not easy to stratification, high pressure, corrosion resistance, non-toxic materials. Elastic rubber, but long service life. Small size, easy to accept, easy to move. * Used in agriculture, industry

At present, we supply a variety of PVC hose including

Steel wire and fiber reinforced flexible PVC hose

PVC garden hose

PVC spray hose

High pressure air hose

PVC gas hose

PVC shower hose

Single wallclear pvc hose

PVC suction hose

welding hose

Layflat hose

detail:

Plastic pipe in the production process, due to the operator of the process and machine operation is not proficient, often lead to plastic pipe appearance of rough surface, the internal jitter ring, uneven wall thickness, roundness is not enough and so on, so the timely adjustment process, excluding Plastic pipe production line failure, to improve product quality.

Plastic pipe production line failure: plastic pipe rough surface

Adjust the process temperature; reduce the cooling water temperature, PE pipe cooling water temperature is 20 ~ 25 ℃; check the waterway, whether there is blockage or insufficient water pressure; check the barrel, nose and other heating ring for damage; Water flow; check the performance of raw materials and batch number; check the mold core temperature, if higher than the die section temperature, lower core temperature; clean the aggregate of the mold;

Plastic pipe production line failure: plastic pipe outer surface of the groove marks

Adjust sizing sleeve outlet pressure, the amount of water required to balance; Adjust the nozzle angle vacuum setting box, so that the pipe cooling uniform; Check the die, sizing sets, cutting machines and other hardware for debris, burrs, etc.