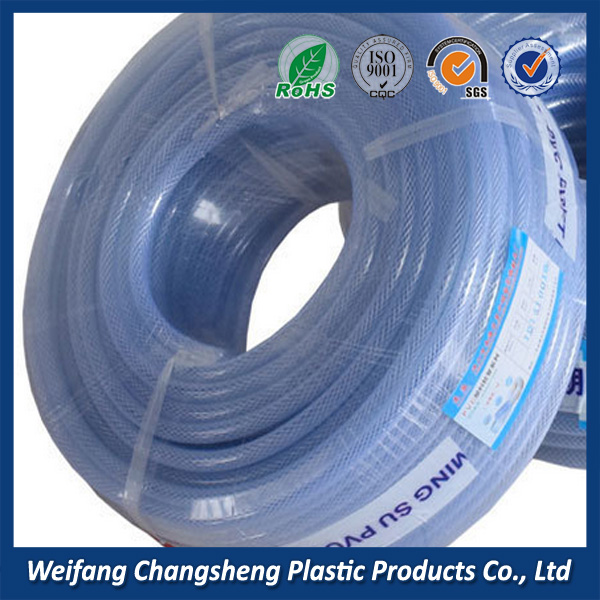

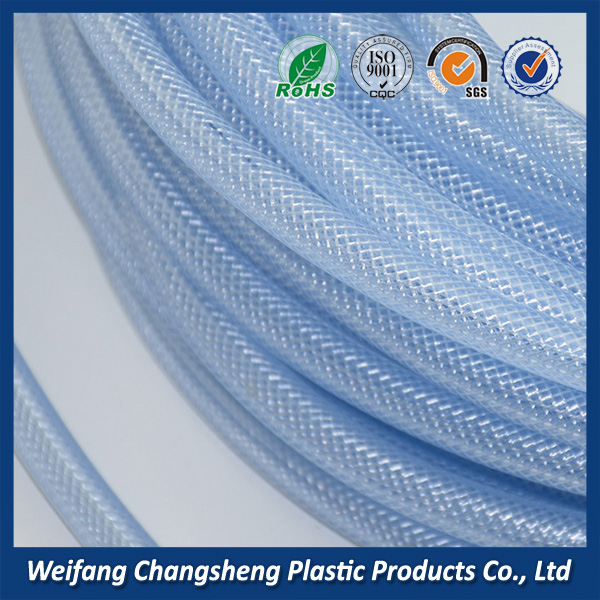

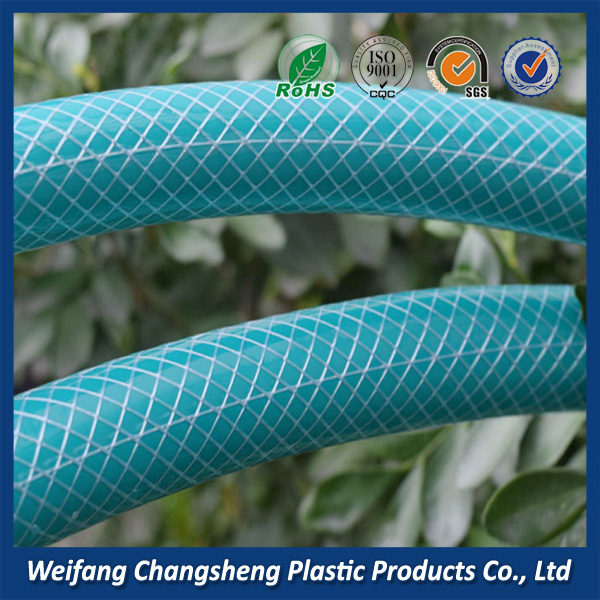

structure PVC3 layer pipe, polyester layer to strengthen the layer, good toughness. Color: The outer and inner layers are clear crystal colors. Provide phthalate-free products. At the same time, we offer tubes for direct consumption of fluid food-grade quality. In line with the German KTW Association standards. application Cooling liquid transport, but also for the food and food packaging industry, beverage delivery, chemical industry and compressed air branch, etc., for a variety of industry

Weifang Changsheng Plastic Co., Ltd. is a professional enterprise of plastic products and plastic machinery. It covers an area of 30000 square meters. Company owns a modernized workshop with more than 20 production lines and complete testing equipment.

For many years, we committed to the improvement of production process and innovation of products, as well as the increasing various of products to meet the demand of market. Rely on the premium quality, advanced technology, standard manage and quality control system, we build long-term cooperation relationship with clients over 20 countries.

As an OEM manufacturer, we can supply products as customers' requirement. We sincerely welcome the domestic and foreign friends to visit us.

detail:

Plastic pipe production line failure: Pipe size tolerance:

Adjust the size of the vacuum can change the size of the park outside; adjust the traction speed can change the size of the park; correction sizing sleeve hole size;

Plastic pipe production line failure: pipe roundness tolerance

Adjust the vacuum setting machine, nozzle angle within the spray box, so that the pipe cooling uniformity; check the vacuum setting machine, the spray tank height of the water table, pressure gauge pressure, so that the spray volume is large and powerful; check the vacuum setting machine, spray box Water temperature conditions, if> 35 ℃, the need to configure the chilled water system or increase the cooling spray box; check the waterway, cleaning the filter; adjust the process; check and correct sizing bore hole garden; Ovality of pipe

Plastic pipe production line failure: pipe wall thickness is not uniform

Adjusting the wall thickness on the mold; adjusting the angle of the nozzle in the vacuum setting machine and the spray box so as to make the pipe cool uniformly; adjusting the outlet diameter of the calibrating sleeve so as to make the water evenly; disassembling the mold and checking whether the screws in the mold are loose and retightening;

Plastic pipe production line failure: plasticizing temperature is too high

Adjust the process; adjust the heating temperature of the mold core, and the interior of the mold ventilation cooling; screw shear heat is too high, replace the screw